Pressure Gauges Range

Hoses Direct offer an extensive range of pressure gauges in glycerine, digital, and dry formats, featuring esteemed brands like Eagle Pro, Hi-Force, Hy-Fitt, Sika, and UFI to ensure quality and reliability. Available in thread sizes ranging from 1/4” to 1/2” in stock with larger sizes available, with choices in BSP and NPT thread types, our selection includes center back or bottom fitting configurations. Hoses Direct's pressure gauge collection guarantees precision and performance for any hydraulic pressure monitoring system.

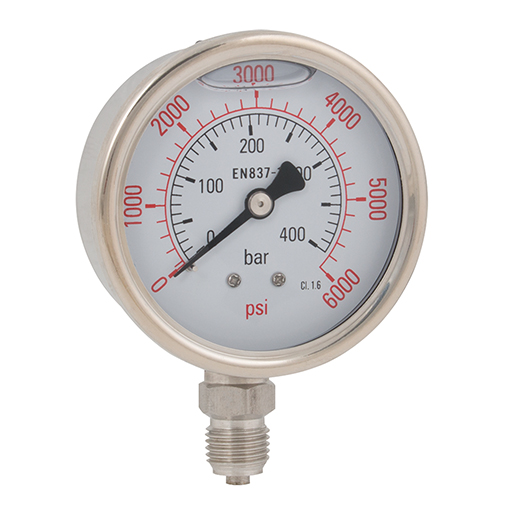

Among our most sought after options are glycerine gauges, also recognised as glycerine-filled pressure gauges. These gauges are filled with glycerine, a clear liquid, serving as a damping medium between the dial face and the pointer mechanism. Glycerine gauges offer features such as vibration damping, extended lifespan, enhanced durability, and steadier readings, making them versatile for industrial applications, particularly in hydraulic and pneumatic systems.

Glycerine Gauges

Vibration Damping:

Effective in applications with vibrations or pulsations.

Absorbs and dampens movements, ensuring a steady readings.

Extended Lifespan:

Reduces wear on internal components, contributing to a longer gauge lifespan.

Enhanced Durability:

Acts as a lubricant, reducing friction and wear within the gauge.

Steadier Readings:

Damping effect results in stable needle movements for accurate pressure readings.

Versatility:

Suitable for various industrial applications, especially hydraulic and pneumatic systems.

Corrosion Resistance:

Provides an additional layer of protection against corrosion in harsh environments.

In contrast, dry gauges which do not contain fluid, provide simplicity, and cost effectiveness. They are easy to install and maintain, making them a budget friendly choice for pressure measurement where liquid filling advantages are unnecessary.

Dry Gauges:

Simplicity:

Simple internal construction without the need for liquid filling.

Cost-Effective:

More budget-friendly compared to liquid-filled counterparts.

Wide Applicability:

Suitable for a broad range of applications, including industrial, commercial, and residential.

Easy Installation:

Straightforward to install and maintain, no special considerations for mounting orientation.

Sensitivity to Vibrations:

May be more sensitive to vibrations, making them suitable for applications without significant vibrations.

Versatility:

Available in a variety of pressure ranges, adaptable to different measurement requirements.

For those seeking advanced precision, our Hoses Direct’s digital gauges are electronic instruments displaying pressure readings numerically on an LCD screen. With high accuracy, easy readability, and durability, these battery-powered gauges find applications across industries where precise pressure measurements are crucial. The measured units can be displayed in bar, psi, mbar, KPa, Mia, kg/cm2, mH20, inchH20.

Digital Gauges:

Accuracy:

Offers high precision in pressure measurements for reliable readings.

Easy Readability:

Numerical display on LCD screens for quick and clear readings.

Flexibility in Units:

Can be programmed to display pressure readings in various units.

Durability:

Resistant to environmental factors like vibration and temperature variations.

Convenience:

Battery-powered for portability, suitable where a wired power source is not available.

Additional Features:

Often includes features like data logging for advanced functionality and screen back lighting

Often includes features like data logging for advanced functionality and screen back lighting

In conclusion, the choice between glycerine-filled, digital, or dry gauges depends on specific application needs. Glycerine-filled gauges excel in stability and longevity, digital gauges offer accuracy and advanced features, while dry gauges provide simplicity and cost-effectiveness. Selecting the ideal gauge should consider environmental conditions, precision requirements, and budget considerations, ensuring a perfect alignment with the demands of your pressure measurement task.

Contact our customer care team on sales@hoses.co.uk or call: 0333 6000 501 for advise on your pressure gauge requirements.