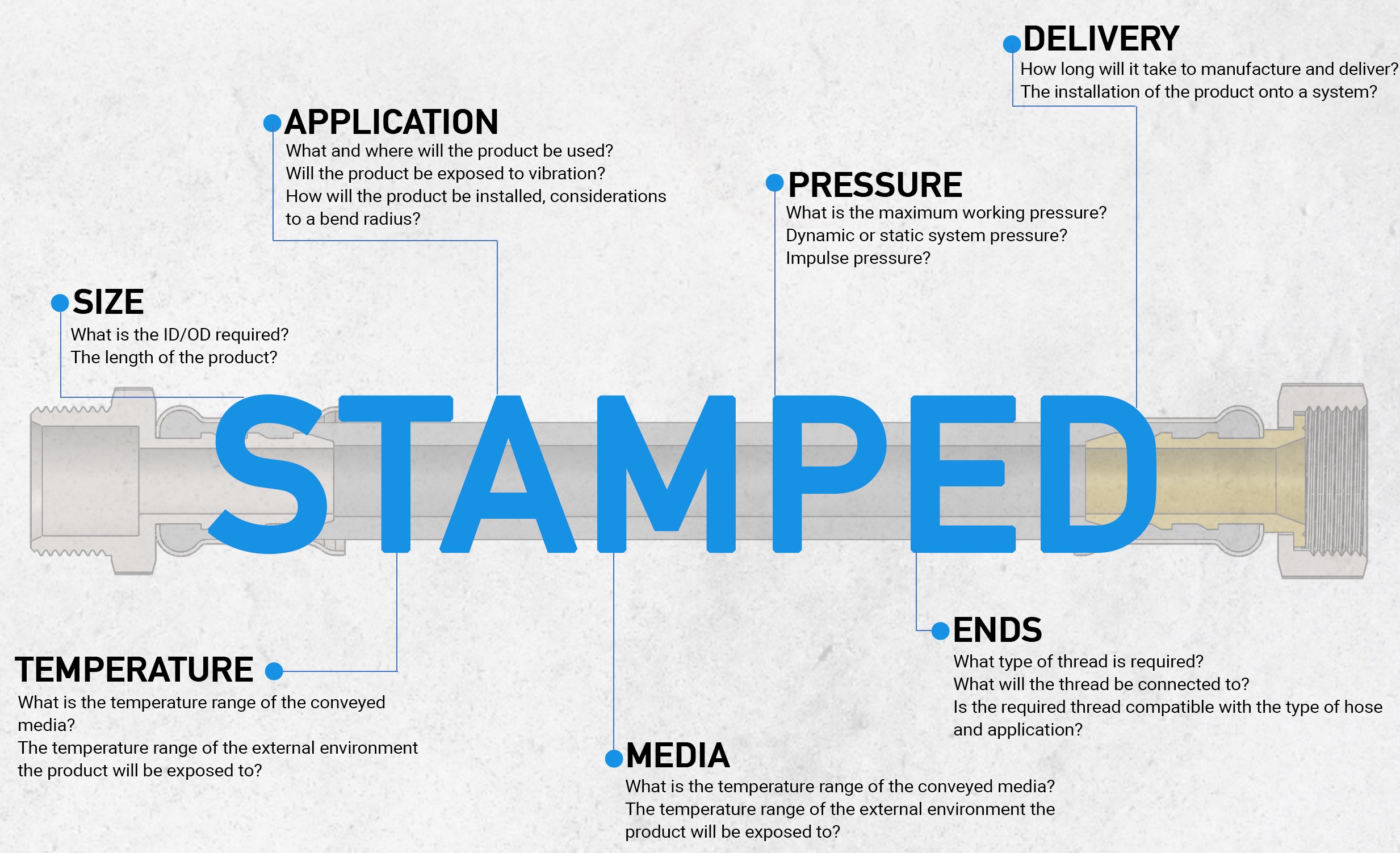

The acronym STAMPED stands for Size, Temperature, Application, Material/Media, Pressure, Ends, and Delivery, is an industry wide recognised practice used by engineers and people within this industry to distinguish the correct identification of the product required to meet a specification. Whether it is for a hose or fittings selection, Hoses Direct endorses STAMPED by utilising the seven parameters to eliminate the possibility of a failure, to increase the efficiency and life cycle of a product and or system.

This article Why STAMPED is Important in A Material World highlights the criteria used to form STAMPED to ensure a leak free connection to determine a suitable selection of the type of hose/fitting required for your application. All seven parameters are as equally important as each other.

Size

Questions to consider:

What is the ID/OD required?

The length of the product?

Considerations should be made to the size to ensure the product can maintain a tolerable flow rate, with the velocity of media running through the product playing a key part which can result in a failure or a poor performance if the correct size is not selected.

Temperature

Questions to consider:

What is the temperature range of the conveyed media?

The temperature range of the external environment the product will be exposed to?

A product not continuously used to its maximum working pressure and temperature limit will serve a longer life expectancy and performance. To increase the life cycle of your product consider a working temperature equal to or greater than both the fluid and ambient temperatures. Temperature tolerances rely on the correct and most appropriate material choice for your application.

Application

Questions to consider:

What and where will the product be used?

Will the product be exposed to vibration?

How will the product be installed, considerations to a bend radius?

A products setting will influence factors such as spikes in pressures, temperatures and expected vibration, which will affect its performance and dependability. Therefore it is crucial to understand not only what the product is exposed to but how it is exposed to environmental factors and surroundings.

Media

Questions to consider:

Which media is being conveyed?

Is the media considered to be corrosive, hazardous or abrasive?

A product in contact with conveying fluids, gases, air, chemicals or oil will need to meet the robust standards to each specialised media to ensure the safety, durability and performance of a system. Considerations to whether the media will flow continuously in the product or if the media is expected to sit within the product will play a part in the product selection.

Pressure

Questions to consider:

What is the maximum working pressure?

Dynamic or static system pressure?

Impulse pressure?

Not only does one need to consider the pressure of the media conveyed within the product, the temperatures inside and outside a system can also affect pressures a product is exposed to. Fluctuating pressures can influence the durability of even the most robust products.

Ends

Ends

Questions to consider:

What type of thread is required?

What will the thread be connected to?

Is the required thread compatible with the type of hose and application?

The choice of fitting connections is endless, therefore it is important to consider factors such as materials, applications, orientation, temperatures and pressures to ensure a leak proof connection. End connections are available in a variety of shapes and sizes, with quick release options available should this meet the specification of an application.

Delivery

Questions to consider:

How long will it take to manufacture and deliver?

The installation of the product onto a system?

Dependant on the choice of product, specialised products may require testing, tagging and certifications which can all be provided by Hydraquip Hose & Hydraulics along with a technical engineer to safely remove and install products to a system.

sales@hoses.co.uk

For further information or questions relating to Stamped, please to not hesitate to contact Hoses Direct via sales@hoses.co.uk. Furthermore should you require any assistance with technical support please contact us on 0333 6000 501