Stainless Steel Hose Assembly

In the world of industrial applications, selecting the right components is crucial for ensuring efficiency, safety, and longevity. Stainless steel hose assemblies stand out due to their robustness, versatility, and high performance across various demanding environments. Whether you're in the automotive, pharmaceutical, or manufacturing industry, understanding why a stainless steel hose assembly is the best choice can significantly impact your operations. This article explores the specifics of stainless steel hose assemblies, exploring their advantages, applications, and why Hoses Direct is your ideal partner for these essential components.

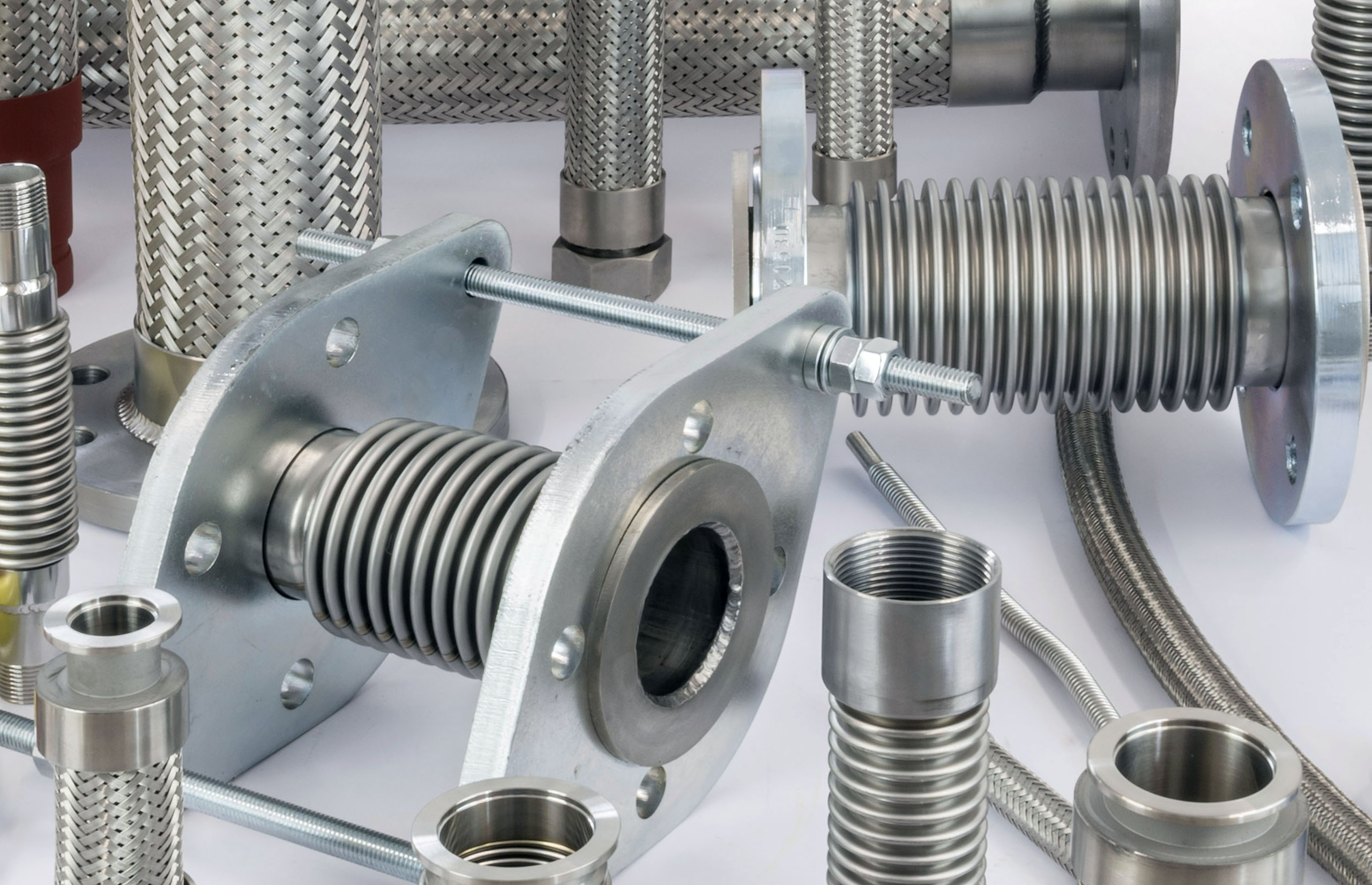

What is a Stainless Steel Hose Assembly?

Stainless steel hose assemblies are designed to transport fluids and gases in harsh environments. Constructed from high-grade stainless steel, these hoses offer exceptional resistance to corrosion, extreme temperatures, and mechanical stress. Unlike traditional hoses, stainless steel variants are engineered to provide superior flexibility and strength, making them indispensable in applications where reliability and durability are paramount. At Hoses Direct, we supply a comprehensive range of stainless steel hose assemblies tailored to meet the stringent requirements of various industries including PTFE lined assemblies, expansion joints and gas & welding hoses.

When Should You Use a Stainless Steel Hose Assembly?

Extreme Temperatures

Stainless steel hose assemblies are particularly advantageous in environments subjected to extreme temperatures. Their inherent ability to withstand both high and low temperatures without compromising structural integrity makes them ideal for applications in sectors like aerospace, automotive, and industrial manufacturing. These hoses maintain their flexibility and performance, ensuring reliable operation even under severe thermal stress.

Chemical Compatibility and Corrosion Resistance

One of the standout features of stainless steel hose assemblies is their exceptional chemical compatibility and resistance to corrosion. This makes them ideal for use in industries where exposure to aggressive chemicals and corrosive substances is common. Stainless steel's inherent properties protect the hoses from deterioration, ensuring longevity and reducing the need for frequent replacements. This resistance extends the life of the hose, providing a cost-effective solution for businesses that handle hazardous materials or operate in harsh chemical environments.

High-Pressure Environments

Stainless steel hose assemblies excel in high-pressure environments due to their robust construction and superior strength. They are designed to endure significant internal pressures without bursting or deforming, making them suitable for hydraulic systems, industrial machinery, and other high-pressure applications. The strength of stainless steel ensures that the hoses can maintain their integrity and function effectively even under extreme pressure, reducing the risk of failure and potential downtime.

Fire Safety and Reliability

Fire safety is a critical consideration in many industrial settings, and stainless steel hose assemblies offer significant advantages in this area. Their non-combustible nature makes them an excellent choice for environments where fire hazards are a concern. Stainless steel can withstand high temperatures without melting or releasing toxic fumes, thereby enhancing safety in the workplace. This makes them particularly suitable for industries such as manufacturing, construction, and transportation, where fire risks must be mitigated.

Vacuum Applications

Stainless steel hose assemblies are also highly effective in vacuum applications, where maintaining a secure and impermeable conduit is essential. These hoses can handle full vacuum conditions without collapsing, ensuring that the integrity of the vacuum system is preserved. The robust construction of stainless steel hoses prevents permeation and leakage, which is crucial for applications requiring a high level of containment and cleanliness.

Industries such as pharmaceuticals, biotechnology, and research and development often rely on vacuum systems, and the use of stainless steel hose assemblies in these settings ensures reliable performance and efficiency.

Flexibility and Overbending Concerns

While stainless steel hose assemblies are known for their durability and strength, they also offer a notable degree of flexibility. This flexibility allows for easier routing and installation, even in complex systems. However, it is important to address concerns regarding overbending, which can compromise the structural integrity of the hose. Proper installation practices and the use of appropriate bend restrictors or supports can mitigate these concerns, ensuring that the hoses maintain their optimal performance.

At Hoses Direct, we provide expert guidance and support to help you select the right stainless steel hose assembly for your specific application, taking into account factors such as bend radius and installation environment. This ensures that you benefit from the flexibility of stainless steel hoses without compromising on safety or functionality.

Benefits of Using a Stainless Steel Hose Assembly

Stainless steel hose assemblies are renowned for their exceptional durability and long lifespan. The robust construction of these hoses allows them to withstand harsh conditions and mechanical stress, making them a reliable choice for demanding applications. This durability translates into reduced maintenance costs and fewer replacements over time, offering significant cost savings for businesses. The long-term reliability of stainless steel hoses ensures that your operations run smoothly and efficiently.

Increased Flexibility and Ease of Use

Stainless steel hose assemblies offer a unique combination of flexibility and strength, making them easy to install and manoeuvre in tight spaces or complex systems. This flexibility is particularly beneficial in applications requiring frequent adjustments or movements, such as in manufacturing processes or automotive systems. The ease of use provided by these hoses simplifies installation and maintenance, reducing downtime and enhancing overall productivity.

Pressure Tolerance

Stainless steel hose assemblies are designed to withstand high pressure levels, making them suitable for applications that involve intense hydraulic or pneumatic operations. Their construction allows them to endure significant internal and external pressures without compromising their integrity. This superior pressure tolerance ensures consistent performance and reliability, which is crucial for maintaining operational efficiency in high-pressure environments.

Industries such as oil and gas, aerospace, and heavy machinery heavily rely on components that can handle high pressures safely and effectively. Stainless steel hose assemblies meet these demands, providing a dependable solution for critical applications.

Temperature and Corrosion Resistance

Stainless steel hose assemblies excel in environments exposed to extreme temperatures and corrosive elements. Their ability to resist oxidation and degradation at high temperatures makes them ideal for use in industries such as chemical processing, power generation, and automotive exhaust systems. Additionally, stainless steel’s natural resistance to corrosion ensures longevity even when exposed to harsh chemicals, saline environments, or outdoor elements.

Aesthetic Appeal

Beyond their functional advantages, stainless steel hose assemblies also offer aesthetic benefits. Their sleek and professional appearance makes them a preferred choice in applications where visual appeal is important, such as in high-end manufacturing environments, showrooms, and cleanrooms. The polished surface of stainless steel hoses not only looks attractive but also resists tarnishing and staining, maintaining a clean and modern look over time.

This aesthetic appeal complements the high performance and durability of stainless steel hoses, making them a well-rounded choice for various applications.

Applications of Stainless Steel Hose Assemblies

Industrial Applications

Stainless steel hose assemblies are widely used across a number of industries due to the benefits and features we have already discussed. They are essential components in machinery, manufacturing processes, and chemical handling systems. Industries such as oil and gas, power generation, and metal fabrication also benefit significantly from the reliability and performance of stainless steel hoses.

Automotive and Transportation Industries

In the automotive and transportation industries, stainless steel hose assemblies play a crucial role in ensuring safety and efficiency. Their high tolerance for extreme temperatures and pressures makes them ideal for use in exhaust systems, brake lines, and fuel systems. The robust construction of these hoses helps to prevent leaks and failures, which is essential for maintaining the reliability and safety of vehicles. Additionally, the flexibility of stainless steel hoses allows for easier installation and maintenance, reducing downtime and improving overall vehicle performance.

Stainless steel hose assemblies also offer significant benefits in heavy-duty transportation applications, such as in trucks, buses, and industrial vehicles. Their resistance to corrosion and wear ensures long-term durability, even in harsh operating conditions.

Aerospace and Aviation Sectors

The aerospace and aviation sectors demand components that can withstand extreme conditions and rigorous use, making stainless steel hose assemblies an ideal choice. These hoses are used in a variety of applications, including fuel lines, hydraulic systems, and air conditioning units. Their ability to endure high pressures and temperatures, combined with their resistance to corrosion, ensures reliable performance and safety in flight operations.

Heating, Ventilation, & Air Conditioning (HVAC) Systems

In HVAC systems, stainless steel hose assemblies are essential for ensuring efficient and reliable operation. Their resistance to high temperatures and corrosion makes them suitable for both heating and cooling applications. These hoses are used in components such as heat exchangers, boilers, and refrigeration units, where they facilitate the transfer of fluids and gases under demanding conditions.

Pharmaceutical and Biotechnology Industries

Stainless steel hose assemblies are highly valued in the pharmaceutical and biotechnology industries due to their ability to maintain purity and integrity in fluid transfer processes. These industries require components that can handle sensitive and potentially hazardous materials without compromising safety or quality. Stainless steel hoses offer excellent resistance to contamination, corrosion, and high temperatures, making them ideal for use in production, research, and laboratory settings.

Research and Development Facilities

Research and development facilities often require versatile and reliable components to support a wide range of experiments and processes. Stainless steel hose assemblies are ideal for these environments due to their durability, flexibility, and resistance to extreme conditions. They are used in various applications, including fluid transfer, chemical handling, and high-pressure experiments.

The robust nature of stainless steel hoses ensures that they can withstand the rigours of continuous use and exposure to different substances, providing consistent performance and reliability. This makes them a valuable asset in research and development settings, where precision and dependability are critical.

Products You May Also Require

In addition to stainless steel hose assemblies, several other products can complement and enhance your systems. These include fittings, adapters, and connectors that ensure secure and efficient connections between hoses and other components. Selecting the right accessories is crucial for maintaining the integrity and performance of your installations.

Hoses Direct offers a comprehensive range of related products, including hydraulic fittings, quick-release couplings, and flexible connectors, designed to meet the specific needs of your applications.

Our extensive stock offering ensures that you can find all the necessary components to complete your system, providing a one-stop solution for your hose assembly requirements.

Why Use Hoses Direct For Your Stainless Steel Assemblies

At Hoses Direct, our technical sales team is dedicated to providing expert advice and support to help you choose the right products for your needs. With extensive industry knowledge and experience, our team can guide you through the selection process, ensuring that you find the best stainless steel hose assemblies and accessories for your specific applications. We pride ourselves on offering personalised service and solutions tailored to meet your unique requirements.

Our commitment to customer satisfaction extends beyond the point of sale, with ongoing support and assistance to ensure that your systems operate efficiently and effectively.

We also offer an online web chat service to provide instant support and answers to your questions. This convenient feature allows you to connect with our knowledgeable representatives in real-time, ensuring that you receive the information and assistance you need without delay.

Whether you have questions about product specifications, compatibility, or availability, our web chat service is here to help.

Summary

Choosing stainless steel hose assemblies offers a multitude of benefits, including exceptional durability, flexibility, and resistance to extreme temperatures and corrosive substances. These attributes make them indispensable in a variety of industries, from automotive and aerospace to pharmaceuticals and HVAC systems. Stainless steel hoses ensure reliable performance, safety, and longevity, making them a cost-effective and efficient solution for many applications.

At Hoses Direct, we are committed to providing high-quality stainless steel hose assemblies tailored to meet the specific needs of your business. Our expert technical sales team and convenient online web chat service ensure that you receive the support and guidance necessary to make informed purchasing decisions. By choosing Hoses Direct, you can be confident in the quality and performance of your hose assemblies, backed by exceptional customer service and industry expertise.

For all your stainless steel hose assembly needs, trust Hoses Direct to deliver the right solutions for your business. Contact our team today to learn more about our extensive product range and how we can support your operations.