How Do Water Pumps Work?

A water pump is a mechanical device designed to move water from one location to another. It operates on the principle of either creating a vacuum to draw water (suction) or pushing water through pipes or hoses (displacement), facilitating the transfer of water across distances or elevations. Water pumps are indispensable tools in a variety of settings, from residential homes to industrial plants, serving purposes such as irrigation, water supply, and flood control.

The history of water pumps stretches back to ancient civilizations, where manual and rudimentary devices were first used to meet the water needs of communities. Over centuries, technological advancements have transformed water pumps from simple hand-operated systems to complex, automated machinery capable of moving vast quantities of water efficiently. The evolution from basic piston pumps to today’s centrifugal and submersible pumps highlights humanity's ingenuity in solving water transfer challenges.

As we delve into the workings of modern water pumps, it's crucial to understand the mechanics behind their operation. In the next section, we'll break down the step-by-step process of how water pumps work, from priming the pump to ensuring continuous operation.

A Step-by-Step Breakdown of How Water Pumps Work

Understanding how water pumps operate requires a look into the sequence of actions that enable these devices to move water efficiently. While the specific steps can vary depending on the type of pump, the fundamental process involves several key stages: priming, motor activation, impeller rotation, and managing the flow of water through to safety measures and shutdown procedures.

Priming the Pump (for certain types of pumps)

Priming is essential for pumps that cannot self-prime. This preparatory step involves filling the pump and suction pipes with liquid to remove air and create a vacuum, enabling the pump to start moving water. Without priming, air pockets could prevent the pump from functioning correctly.

Motor Activation and Impeller Rotation

Once primed, the motor activates, driving the rotation of the impeller—a rotating component designed to impart energy to the fluid. As the impeller spins, it pushes water away from its centre, utilising centrifugal force to move the water through the pump and into the discharge pipe.

The Suction Phase and Discharge Phase

During the suction phase, water is drawn into the pump due to the vacuum created by the moving impeller. Following this, the discharge phase sees the water being expelled from the pump under pressure, facilitated by the impeller's design and rotation speed. This phase is crucial for the effective movement of water to its intended destination.

Regulating the Flow and Continuous Operation

Flow regulation is managed through valves and adjustments in the pump's speed, ensuring the desired rate and pressure of water delivery. Continuous operation is maintained by monitoring the pump's performance and adjusting as needed to meet the system's demands.

Safety Measures and Shutting Down Procedures

Safety measures are integral to prevent damage to the pump and the system it serves. This includes overload protection, thermal cut-outs, and regular maintenance checks. Shutting down a pump involves carefully halting the motor and ensuring the system is depressurised and drained if necessary, to avoid damage or operational issues upon restart.

In the next section, we will explore the various types of water pumps available and their specific mechanisms, from centrifugal pumps favoured for their efficiency to submersible pumps designed for underwater operations.

Types of Water Pumps and Their Mechanisms

Water pumps come in a variety of designs, each suited to specific applications based on the needs of water movement, pressure requirements, and operational environment. Understanding the mechanisms behind different types of water pumps can help in selecting the right pump for a given task.

Centrifugal Pumps and Their Uses

Centrifugal pumps are among the most commonly used water pumps, characterised by their method of moving water through the action of a rotating impeller. These pumps are ideal for applications requiring a steady, high-volume water flow, such as in municipal water supply systems, cooling systems, and for irrigation purposes. The simplicity of their design contributes to their popularity and wide-ranging applicability.

Submersible Pumps: Deep Dive Operation

Submersible pumps are designed to operate while fully submerged in the water they are pumping. This design eliminates the need for priming and allows these pumps to provide efficient water movement from deep wells, boreholes, or reservoirs. Their sealed, waterproof construction makes them suitable for underwater applications, including drainage, sewage pumping, and general industrial pumping.

Positive Displacement Pumps: Ensuring Consistent Flow

Positive displacement pumps move water by trapping a fixed amount and forcing (displacing) that trapped volume into the discharge pipe. This type of pump is beneficial in applications requiring a precise volume of water to be moved per cycle, offering a consistent flow regardless of the system pressure. They are commonly used in chemical processing, food manufacturing, and in any setting where accurate dosing is crucial.

High-Pressure Pumps for Intensive Applications

High-pressure pumps are designed to deliver water at high pressures, suitable for applications such as pressure cleaning, misting systems, and industrial processes where high-pressure water jets are required. Their robust construction ensures durability and reliability under demanding conditions.

Additional Types: Rotary, Reciprocating, Peristaltic, and Diaphragm Pumps

Rotary pumps use a rotating mechanism to create a vacuum that draws in water, ideal for transferring viscous liquids or oils.

Reciprocating pumps, with their back-and-forth motion, offer high precision in fluid handling, useful in research and laboratory settings.

Peristaltic pumps compress and release a flexible hose or tube, pushing the fluid through the pump. This design is favoured for sterile applications since the fluid does not come into contact with moving parts.

Diaphragm pumps utilise a flexible diaphragm that moves up and down to create a variable-sized chamber, drawing in and expelling water. They are often used in situations requiring a safe, leak-free operation.

In the following section, we will delve into turnkey water pump solutions provided by Hoses Direct, highlighting products like lever lock water couplings and layflat hose, and how they integrate seamlessly with various types of water pumps for efficient water management.

Turnkey Water Pump Solutions from Hoses Direct

At Hoses Direct, we understand that finding the right water pump solution extends beyond the pump itself. It encompasses a comprehensive approach that includes compatible accessories and fittings to ensure optimal performance and durability. Our range of products caters to a wide array of water pump applications, providing turnkey solutions for both commercial and individual needs.

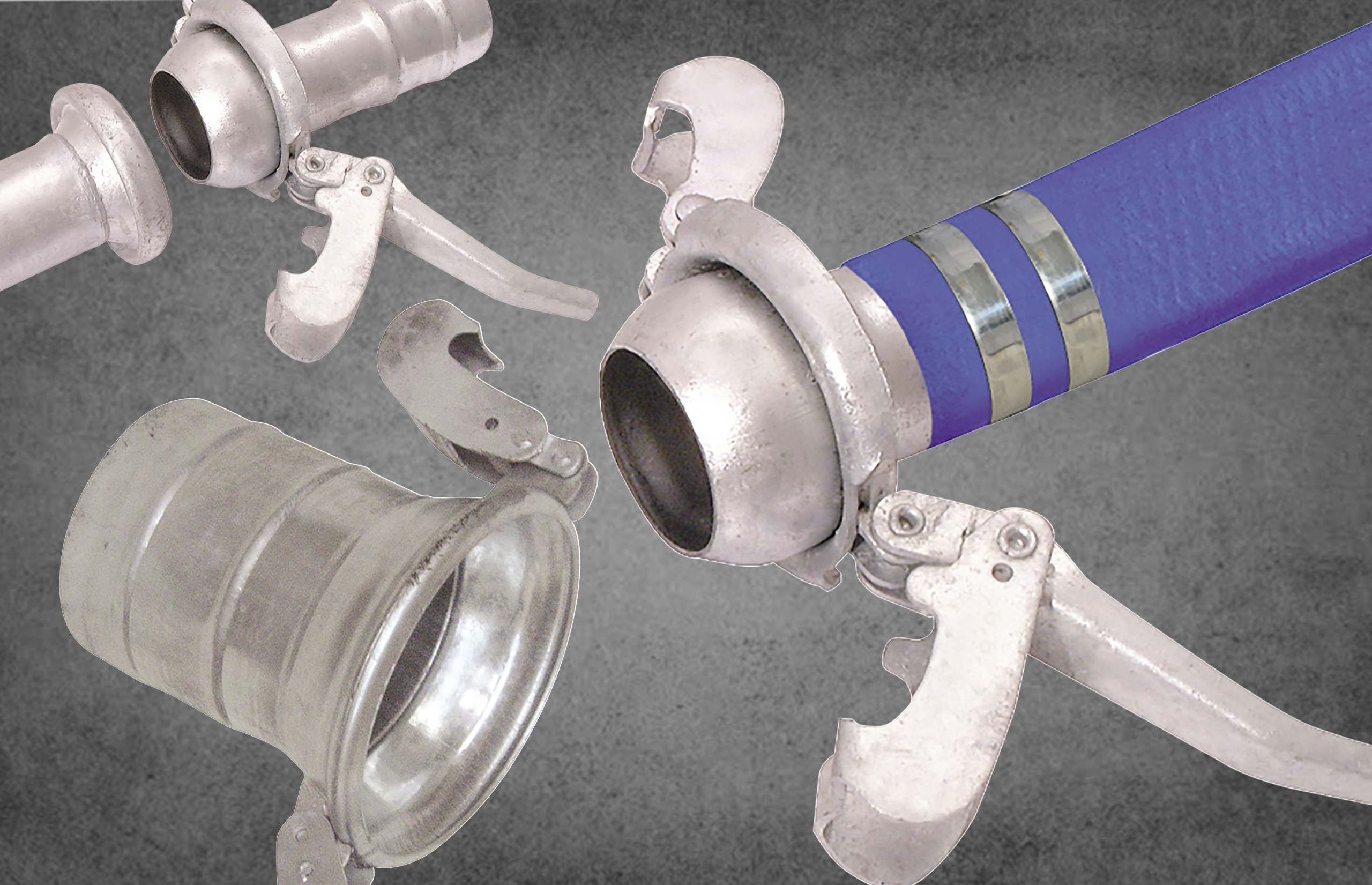

Lever Lock Water Couplings

Lever lock water couplings are an essential component for many pumping systems, offering a secure and easy-to-use connection between hoses and pumps. Designed for quick assembly and disassembly, these couplings minimise downtime and enhance operational efficiency. They are particularly useful in agricultural irrigation and industrial water systems where reliability and speed are paramount. Our lever lock couplings are available in various sizes and materials to suit different pressures and types of use, ensuring a perfect fit for your specific pumping requirements.

Layflat Hose

The layflat hose is another integral part of our water pump solutions, recommended for its flexibility and ease of storage. This type of hose is designed to lay flat when not in use, making it ideal for emergency water supply, irrigation, and dewatering applications. Its lightweight design allows for easy handling and deployment, while its durability ensures it can withstand various environmental conditions and pressures. At Hoses Direct, our layflat hoses come in a range of diameters and lengths, enabling a tailored approach to meet the unique demands of your water transfer projects.

These products, among others in our extensive catalogue, are designed to integrate seamlessly with water pumps, providing a holistic solution to meet the complex needs of our diverse clientele. Whether you're involved in agricultural, industrial, or residential water management, Hoses Direct offers the expertise and product range to support your water pumping operations.

Next, we will explore common applications and special requirements for water pumps, highlighting the versatility of our products in meeting the challenges faced in household water supply systems, agricultural irrigation techniques, and industrial process requirements.

Common Applications and Special Requirements

Water pumps serve a pivotal role across various sectors, each with its unique demands and challenges. From domestic water supply to agricultural irrigation and industrial processes, the versatility of water pumps is evident in their wide-ranging applications. Understanding these applications and their specific requirements is crucial for selecting the right pump and accessories.

Household Water Supply Systems

In residential settings, water pumps are primarily used to ensure a consistent and reliable water supply. Submersible pumps, for instance, are commonly installed in wells to provide households with direct access to groundwater, while booster pumps enhance water pressure in homes with insufficient municipal water pressure. The selection of a suitable pump ensures that water is delivered efficiently and safely to all parts of the home.

Agricultural Irrigation Techniques

Agriculture relies heavily on water pumps for irrigation, making it possible to cultivate crops in areas without natural precipitation. Centrifugal pumps are often favoured for surface irrigation, thanks to their ability to move large volumes of water quickly. Drip irrigation systems, on the other hand, may use positive displacement pumps for their ability to deliver water at precise rates.

Industrial Process Requirements

In the industrial sector, pumps are integral to processes involving cooling, washing, and waste management, among others. High-pressure pumps are essential for tasks requiring forceful water jets, while chemical processes may necessitate diaphragm or peristaltic pumps for their ability to handle corrosive or sensitive fluids without contamination. The compatibility of Hoses Direct’s hoses and couplings with these pumps ensures that industrial operations can maintain high standards of efficiency and safety.

In the conclusion of our guide, we will summarise the importance of choosing the right water pump and accessories, reinforcing the value of expert advice and quality products in achieving efficient and reliable water management solutions.

Get In Touch

Hoses Direct offers an extensive selection of pumps, lever lock water couplings, layflat hoses, and other essential accessories.

Our expertise and product range are designed to meet the comprehensive needs of our diverse clientele, ensuring reliable and efficient water management across all sectors.

Whether you're involved in agriculture, industry, or managing a household water system, the success of your water pumping operations relies on the quality of your equipment and the knowledge behind its selection and maintenance. Hoses Direct remains committed to supplying high-quality, reliable solutions tailored to the varied demands of our customers, reinforcing our role as a trusted partner in water management.

Call: 0333 6000 501

Email: sales@hoses.co.uk

-

From: £68.75

-

From: £148.52