What Are the Most Common Types of Hydraulic Hose Fittings?

Hydraulic fittings are essential components in any fluid power system, serving as the conduit for controlling the flow and pressure of hydraulic oil. These fittings ensure the secure connection of hoses, pipes, and tubes within hydraulic machinery, enabling the efficient transmission of fluid power across various parts of the system. The diversity in hydraulic applications necessitates a broad spectrum of fitting types, each designed to meet specific standards of pressure, size, and fluid compatibility. At Hoses Direct, we pride ourselves on offering an extensive selection of hydraulic fittings, designed to cater to a wide range of industrial needs, ensuring reliability and performance.

In the next section, we will delve into the various types of hydraulic hose fittings available, including the distinctions between permanent and reusable fittings and the different fitting ends and connector types, to provide a deeper understanding of the options at your disposal.

Types of Hydraulic Hose Fittings Explained

Permanent Vs Reusable Fittings

When selecting hydraulic hose fittings, one of the primary considerations is whether to opt for permanent or reusable fittings. Permanent fittings, often used in critical applications, require crimping equipment to attach them securely to the hose, offering a robust and leak-proof connection ideal for high-pressure systems. These fittings are preferred for their durability and reliability, especially in environments where safety and performance are paramount.

Conversely, reusable fittings provide the flexibility of being assembled or repaired on-site without the need for specialised crimping tools. They are particularly valuable in situations where quick repairs are necessary, reducing downtime and maintaining productivity. Although they are convenient, it's crucial to ensure their compatibility and correct installation to prevent leaks and maintain system integrity.

Fitting Ends and Connector Types

Understanding the various fitting ends and connector types is crucial for ensuring compatibility and performance in hydraulic systems. Connector types are categorised based on their design and the method they use to seal and hold hydraulic lines.

O-Ring Face Seal (ORFS)

The O-Ring Face Seal offers the highest level of leak protection, making it ideal for high-pressure applications. This type of fitting uses an O-ring located in the face of the fitting, which compresses on a flat surface to create a strong, leak-proof seal. ORFS fittings are widely appreciated for their effectiveness in preventing leaks, even in systems subject to vibrations and fluctuations in pressure.

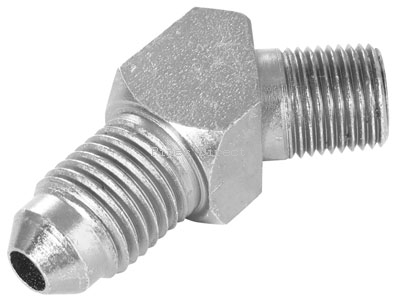

Mated Angle and Tapered Threads

JIC (Joint Industry Council) fittings are known as mated angle type fittings and they play a significant role in hydraulic systems as they offer a reliable and standardised solution for connection hoses and components. Characterised by their 37-degree flare fitting design, JIC fittings ensure a strong metal-to-metal sealing surface that is both robust and leak-resistant. Their universal acceptance and ease of use make them a popular choice across various industries, underlining their importance in ensuring the efficiency and reliability of hydraulic systems.

Tapered threads, such as BSPT (British Standard Pipe Thread) and NPT (National Pipe Tapered), seal by the thread interference, and they require thread sealant to ensure a leak-proof connection. These fittings are straightforward to install and are suitable for a range of applications, from low to high pressure.

In the upcoming section, we'll guide you on choosing the right hydraulic hose fittings for your application, taking into consideration factors such as identification, application use cases, and material considerations. This guidance will include practical advice on selecting the most appropriate fittings to meet the specific requirements of your hydraulic systems, ensuring optimal performance and reliability.

Choosing the Right Hydraulic Hose Fittings

How to Identify Hydraulic Hose Fittings

Identifying the correct hydraulic hose fittings is critical for ensuring compatibility and optimal performance of your hydraulic system. The process involves examining the fitting's size, thread type, and configuration. It's essential to measure the outer diameter of the thread for male fittings and the inner diameter for female fittings to determine the thread size accurately. Additionally, the thread pitch, or the distance between threads, should be measured to identify the thread type, such as NPT, BSPP (British Standard Pipe Parallel), or Metric. Understanding the orientation and type of seal required is also crucial, as this will influence the fitting's ability to provide a leak-proof connection.

Hoses Direct offers a comprehensive range of hydraulic hose fittings, accompanied by detailed product specifications and expert support to assist in the identification process. Our team is always ready to provide the guidance needed to ensure you select the right fittings for your specific requirements.

Factors to Consider When Choosing End Fittings

Selecting the appropriate end fittings for a hydraulic hose involves several critical considerations beyond just size and type. The application's specific requirements, such as pressure, fluid type, and environmental conditions, play a significant role in determining the most suitable fittings.

Application Use Cases

The nature of the application significantly influences the choice of hydraulic hose fittings. High-pressure systems, for example, require fittings designed to withstand the system's pressure without leaking or failing. Similarly, applications involving corrosive fluids may necessitate fittings made from materials such as stainless steel that offer superior chemical resistance. Understanding the operational demands of your application ensures that the selected fittings will perform as required, providing a reliable and efficient hydraulic system.

Material Consideration

The material of the hydraulic hose fittings is another crucial factor to consider, as it must be compatible with the hydraulic fluid and the application's environmental conditions.

Steel fittings are widely used for their strength and durability, suitable for high-pressure environments.

Stainless steel fittings offer excellent corrosion resistance, making them ideal for harsh conditions and applications involving corrosive fluids.

Brass fittings are commonly used in lower pressure settings and are compatible with a wide range of fluids, offering good corrosion resistance.

Plastic fittings are lightweight and resistant to corrosion, suitable for less demanding applications.

Aluminium fittings combine lightweight properties with good corrosion resistance, used in applications where reducing weight is beneficial.

Hoses Direct provides a wide selection of hydraulic hose fittings in various materials, ensuring that whatever your specific application demands, we can supply the right fittings to meet your needs.

In the conclusion, we will recap the critical aspects of selecting the most common types of hydraulic hose fittings, underlining the importance of making informed choices to maintain the efficiency and reliability of your hydraulic systems.

Conclusion

Choosing the right hydraulic hose fittings is a critical decision that impacts the efficiency, safety, and reliability of hydraulic systems. Through this guide, we've explored the various types of fittings available, including permanent and reusable options, and delved into the different connector types such as O-Ring Face Seal (ORFS), Mated Angle, and Tapered Threads. We've also highlighted the significance of JIC fittings in providing a robust solution for hydraulic connections.

Identifying the correct fittings requires a comprehensive understanding of the system's requirements, including the size, thread type, and material compatibility. Factors such as the application's pressure demands, the type of fluid being transported, and environmental conditions must be carefully considered to ensure optimal performance. By choosing fittings based on these criteria, including material considerations like steel, stainless steel, brass, plastic, and aluminium, you can ensure a durable and efficient hydraulic system.

At Hoses Direct, we are committed to offering our customers a wide array of high-quality hydraulic hose fittings, backed by the expertise to help you make the right choice for your specific applications. Whether your needs are for high-pressure environments, corrosive conditions, or specific material requirements, contact our knowledgeable support team who are ready to assist from our extensive selection of products available.

-

From: £8.78