Pressure relief valves are a fundamental component in hydraulic systems, safeguarding equipment from potential damage caused by excessive pressure build-up. Whether you’re dealing with agricultural machinery, construction equipment, or industrial hydraulics, these valves play a critical role in maintaining system stability and safety.

They’re designed to automatically release pressure when it exceeds a pre-set limit, thus preventing catastrophic failures that could lead to costly downtime and even safety risks for operators.

In the first section, we will explore exactly what a pressure relief valve is and its core purpose within hydraulic systems.

What Is a Pressure Relief Valve? Understanding Its Purpose

A pressure relief valve is a critical safety component designed to protect hydraulic systems from excessive pressure. In essence, it acts as a gatekeeper—opening only when the pressure in the system exceeds a specific, predetermined level. This helps to maintain safe pressure limits, preventing damage to hoses, fittings, pumps, and other crucial parts of the system. By venting excess pressure, the valve helps ensure that hydraulic equipment continues to function without unexpected failures.

These valves are not just about protection; they are fundamental to maintaining the efficiency and longevity of hydraulic systems. Without pressure relief valves, the risk of a system overpressure could lead to burst lines or damaged components, which ultimately impacts productivity and safety.

In the following section, we’ll explore why pressure relief valves are so vital for overall safety within hydraulic systems, providing insights into their safety benefits and why they’re indispensable in many industries.

Why Are Pressure Relief Valves Important for Safety?

Pressure relief valves are integral to maintaining safety across hydraulic systems by preventing the risks associated with overpressure. When pressure builds beyond safe limits, there is a genuine danger of equipment failure, which can lead to hazardous situations for operators and costly repairs. Pressure relief valves help to avert these risks by acting swiftly to release any excess pressure, ensuring that the system remains within its safe operating limits.

Beyond just protecting equipment, pressure relief valves are also crucial for operator safety. Overpressurised hydraulic systems can lead to sudden line bursts, leaking fluids, or even catastrophic system failures, all of which pose significant risks to anyone in proximity. By keeping pressure levels in check, these valves reduce the likelihood of such incidents, creating a safer working environment.

Adherence to industry safety standards also often requires the use of pressure relief valves to meet regulatory compliance. This means that using these valves not only improves safety but also ensures that operations comply with industry guidelines, which is essential for responsible operation.

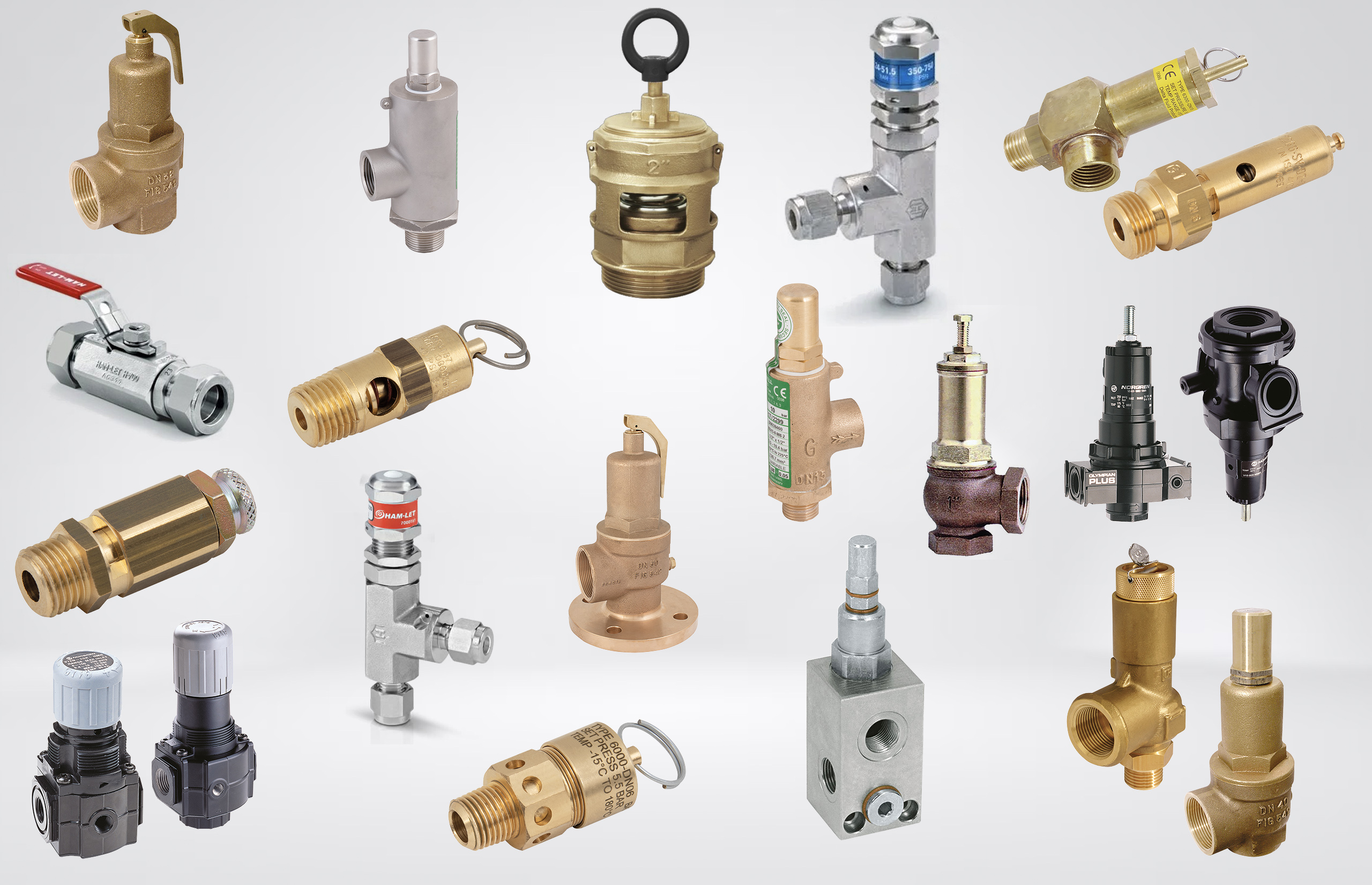

Types of Pressure Relief Valves

Pressure relief valves come in several types, each suited to different applications and system requirements. The two most common types are direct-acting pressure relief valves and pilot-operated pressure relief valves. Understanding these variations is key to selecting the appropriate valve for your specific hydraulic needs.

Direct-acting pressure relief valves are simpler in design, often used for systems that require fast response to sudden pressure increases. They operate by using a spring mechanism that directly counteracts system pressure, offering a quick and straightforward method of pressure control. These valves are generally used in low-flow systems or where pressure regulation requirements are not too complex.

Pilot-operated pressure relief valves, on the other hand, are more advanced and suitable for systems requiring greater precision and stability. These valves function through a combination of pilot and main valves, providing a smoother operation at higher pressures or in systems with variable demands. This makes them ideal for more complex hydraulic systems, where maintaining constant pressure is critical for system reliability.

Selecting the Right Pressure Relief Valve

Selecting the right pressure relief valve is crucial for the safety, efficiency, and reliability of your hydraulic system. There are several considerations to take into account, which ensure that the valve not only fits the technical requirements of your system but also provides optimal performance for your specific application.

Factors to Consider When Choosing a Pressure Relief Valve

When choosing a pressure relief valve, it’s essential to consider the specific needs of your hydraulic system. The selection process should involve examining critical factors such as the system’s flow rate, pressure range, and material compatibility. The valve needs to handle the maximum flow of hydraulic fluid in the system without causing excessive pressure build-up. Moreover, selecting the right pressure range ensures that the valve will activate precisely when needed to protect the equipment. Material compatibility is equally important to ensure the valve resists the fluids used in the system and withstands the environmental conditions of your application.

Flow Rate, Pressure Range, and Material Compatibility

The flow rate represents the volume of hydraulic fluid that the valve must handle, and it varies depending on the system’s size and purpose. Ensuring the valve can manage the system’s maximum flow is crucial for its effectiveness. The pressure range defines the limits within which the valve operates safely, and it’s essential to match the valve’s pressure rating with your system’s working pressure to avoid malfunction. Material compatibility ensures that the valve’s construction is suitable for the hydraulic fluid and the working environment, thus preventing corrosion or degradation.

Sizing a Pressure Relief Valve for Optimal Performance

The size of the pressure relief valve significantly affects its ability to control pressure correctly. An undersized valve may fail to relieve excess pressure effectively, while an oversized one might result in unnecessary opening or instability. Proper sizing is based on understanding both the system’s flow and pressure requirements, along with the operational dynamics. By ensuring accurate sizing, you help prevent costly equipment failures and extend the overall lifespan of the hydraulic system.

Understanding Pressure Relief Valve Ratings and Specifications

Pressure relief valves come with specific ratings that reflect their operational capabilities, such as maximum allowable pressure, temperature limits, and flow capacities. Understanding these specifications is crucial to selecting a valve that not only fits the technical requirements of your system but also complies with industry standards and safety regulations. Matching these ratings to your system’s demands will help ensure reliable performance under varying conditions.

In the next section, we’ll discuss the importance of regular maintenance and testing of pressure relief valves, providing guidance on how to keep these vital components functioning safely and efficiently.

Maintaining and Testing Pressure Relief Valves

Ensuring the proper maintenance and testing of pressure relief valves is key to sustaining their performance and prolonging the lifespan of your hydraulic systems. Regular care not only keeps them operating efficiently but also guarantees that they are always ready to respond when needed, preventing unexpected system failures.

Regular Inspection and Maintenance Best Practices

Pressure relief valves should be routinely inspected to check for any signs of wear, corrosion, or obstruction that could affect their performance. This includes visually inspecting the valve for damage, testing its responsiveness to ensure that it releases pressure at the specified limit, and cleaning any build-up that might hinder its function. Routine maintenance also involves ensuring all components, such as springs and seals, are in good condition and replacing them if any degradation is found.

A proactive approach to maintaining pressure relief valves helps avoid sudden malfunctions, which could lead to unscheduled downtime or serious equipment damage. Preventative maintenance is particularly important in industries like agriculture or construction, where heavy-duty operations place a lot of stress on hydraulic systems.

Next, we’ll look at the range of pressure relief valves available at Hoses Direct and how our products meet the needs of various hydraulic systems.

Pressure Relief Valves Available at Hoses Direct

At Hoses Direct, we offer an extensive range of pressure relief valves designed to cater to a wide array of hydraulic systems. Whether you need a straightforward solution for a simple setup or a more advanced valve for complex systems, our selection ensures that you can find the perfect match for your requirements.

High-Quality, Reliable Valves at Competitive Prices

Quality is at the core of every product we offer at Hoses Direct. We understand the importance of both performance and value, which is why we provide pressure relief valves that are not only robust and reliable but also available at competitive prices.

Our customers benefit from high-quality valves that meet strict industry standards without compromising on budget, making them an ideal choice for both large-scale industries and individual users seeking dependable components.

How Our Customer Support Helps You Find the Right Pressure Relief Valve

Choosing the correct pressure relief valve can be challenging, given the technical considerations involved. At Hoses Direct, our experienced support team is ready to help guide you through the selection process, ensuring you choose a valve that fits your specific system requirements.

Whether you need advice on sizing, material compatibility, or performance specifications, our team is committed to providing personalised assistance. We take pride in helping our customers find the most effective solution, reducing the risk of pressure-related issues and enhancing system reliability.

Summary

Pressure relief valves are an essential part of any hydraulic system, offering protection against the dangers of overpressure and ensuring smooth, safe operation. Understanding the various types of pressure relief valves, their functions, and the applications they serve is vital to making informed decisions that keep your system efficient and safe.

At Hoses Direct, we are committed to providing high-quality pressure relief valves suitable for a wide range of industries, from agriculture to manufacturing. Our expertise and customer support ensures you get the right valve for your needs, maintaining safety, reliability, and operational performance.

If you’re looking for assistance in selecting the perfect pressure relief valve or need more information on our extensive range, our team at Hoses Direct is here to help. Your hydraulic system’s safety is our priority, and our products are designed to give you peace of mind in your operations.